Nouveau mode de paiement

Comme vous le savez, notre souhait le plus cher est de vous SATISFAIRE. Pour ce faire, on enrichit nos moyens de paiement et ajoutons une nouvelle option. Les chèques UP […]

Comme vous le savez, notre souhait le plus cher est de vous SATISFAIRE. Pour ce faire, on enrichit nos moyens de paiement et ajoutons une nouvelle option. Les chèques UP […]

La MJC vous propose un stage de vacances “Comédie musicale” sur le thème un monstre à Paris du 29 avril au 03 mai 2024. Pendant ce stage les enfants créeront […]

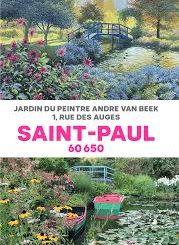

La MJC avec les groupes peintre adultes et art floral, organise une sortie au jardin du peintre André Van Beek à Saint Paul. Le jeudi 30 mai 2024, départ de […]

Mercredi 17 Avril 2024 Vendredi 19 Avril 2024 Oasis de couleur Merci de me répondre tout de suite si vous espérez venir au prochain atelier, car Véronique dois commander les […]

rétrospective Il y a un mois, Little Swing organisait son stage de west coast swing avec Abélia et Zakéo , https://youtu.be/3vait_lxk1U?si=Q8IO7ehvq9Ss6ViO dans notre jolie salle du centre socio culturel Presque […]

Après une première année opérationnelle, la nouvelle équipe souhaite recueillir vos avis et envies. Merci de consacrer quelques minutes à ce questionnaire, qui nous aidera à répondre le mieux possible […]

Mercredi 20 Mars 2024 à 18h Vendredi 22 Mars à 14h Composition de Pâques. Vous amenez : Je propose de commander des Anthuriums verts pour celles qui le désirent, réponse limite […]

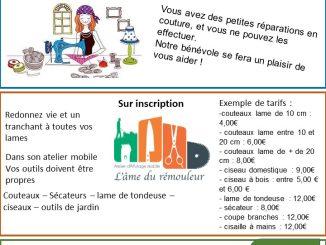

Vous avez des petites réparations en couture, des objets qui ne fonctionnent plus ou encore des lames à affuter ? Pourquoi hésitez ! venez le 24 février à notre Repair […]

La MJC vous propose un atelier théâtre adultes du 4 au 8 mars 2024 de 18h30 à 21h00. Animé par Aurélie notre animatrice théâtre. Les places sont limitées à 12 […]

STAGE WEST COAST SWING INEDIT chez Little Swing : 24 & 25 fevrier ! C’est dans un mois Un stage familial, où on se dit : “oui ça je peux […]

Compo de boucles Mercredi 14 à 18h Vendredi 16 à 14h Vous amenez une assiette plate sans motif. Vous pouvez disposer cette assiette sur un bol de la même couleur […]

Copyright © 2024 | Thème WordPress par MH Themes