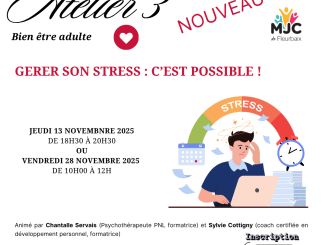

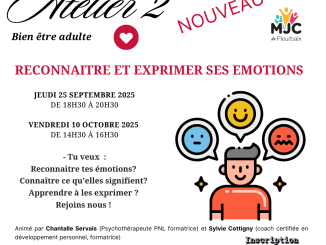

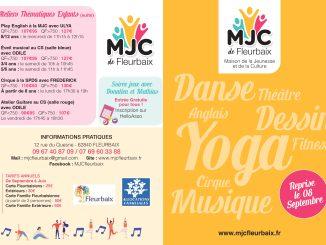

La MJC de Fleurbaix ouvre ses inscriptions pour l’année 2025/2026.

La MJC de Fleurbaix ouvre ses inscriptions pour l’année 2025/2026, qui se font directement en ligne en cliquant sur le lien suivant. https://mjc-de-fleurbaix.s2.yapla.com/fr N’oubliez pas de lire la page explicatif […]